Bimetallic Caij nplooj ntoos hlav rau Thermometer

Khoom taw qhia

Lub caij nplooj ntoos hlav bimetal yog ib hom kev ntsuas qhov ntsuas kub, uas yog tsim los ntawm ob daim hlau nrog sib txawv coefficients.Nws tsuas yog paub qhov ntsuas kub thiab tswj los ntawm cov nplooj ntawv caij nplooj ntoos hlav laminated los ntawm cov hlau sib txawv.

Cov hauv qab no yog cov lus qhia ntxaws ntxaws txog cov yam ntxwv thiab kev siv cov xwm txheej ntawm bimetallic springs los ntawm peb yam: kev taw qhia cov khoom, cov ntsiab lus ua haujlwm thiab daim ntawv thov.

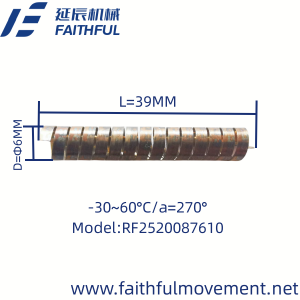

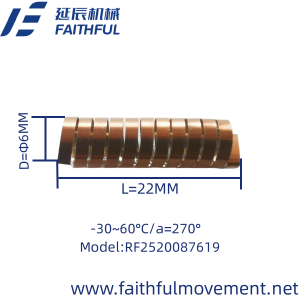

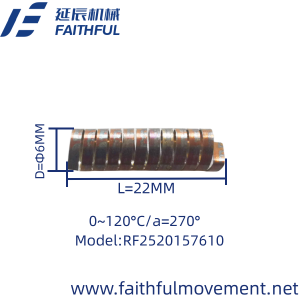

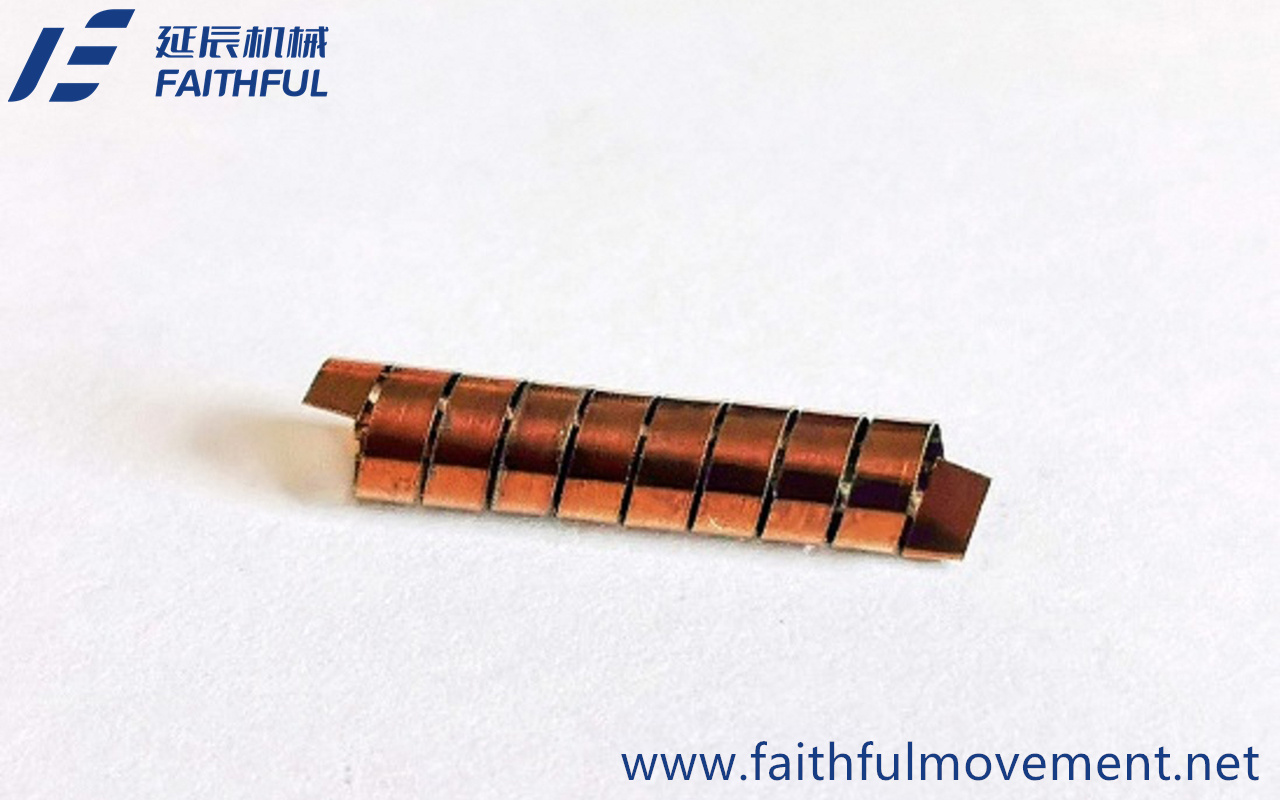

1. Kev taw qhia txog cov khoom lag luam txhawm rau txhawm rau paub qhov ntsuas kub, qee cov cuab yeej ntsuas kub feem ntau yuav tsum tau, xws li cov ntsuas hluav taws xob hluav taws xob, cov ntsuas kub infrared thiab lwm yam.Lub caij nplooj ntoos hlav bimetallic yog lub tshuab ntsuas kub, uas muaj cov yam ntxwv ntawm cov qauv yooj yim, tus nqi qis, kev ruaj ntseg zoo, thiab dav siv qhov kub thiab txias.Nws cov khoom tseem ceeb yog tsim los ntawm ob daim ntawv hlau nrog sib txawv expansion coefficients, thiab yog tsau los ntawm lub caij nplooj ntoos hlav quab yuam tas li.Thaum qhov kub hloov pauv, qhov nthuav dav coefficients ntawm cov hlau sib txawv yog qhov sib txawv, uas ua rau lub caij nplooj ntoos hlav deformation, uas yog hloov mus rau qhov txav ntawm tus taw tes qhia qhov kub thiab txias.

2. Kev ua hauj lwm hauv paus ntsiab lus Rau bimetallic springs, lub hauv paus ntsiab lus ntawm kev ua hauj lwm yog raws li thermal expansion zog ntawm cov hlau sib txawv, yog li cov hlau xav tau yog feem ntau zoo sib xws rau ib puag ncig uas cov khoom tsim.Thaum qhov kub hloov pauv, lub caij nplooj ntoos hlav nplooj yuav tsim khoov deformation, thiab cov khoom siv sib kis yuav hloov cov deformation mus rau qhov txav ntawm tus taw tes, kom paub qhov ntsuas kub.

Cov khoom kub

3. Daim ntawv thov scenarios Bimetallic springs yog siv dav hauv kev tsim khoom, khoom siv hauv tsev thiab khoom siv hluav taws xob, nkoj aviation thiab kev tshawb fawb tshawb fawb thiab lwm yam haujlwm:

1).Kev tsim khoom lag luam: feem ntau yog siv rau hauv lub sijhawm uas yuav tsum tau saib xyuas qhov kub thiab txias, xws li cov chaw tsim hluav taws xob, cov nroj tsuag tshuaj, qhov cub kub, kev cob qhia, thiab lwm yam.

2).Cov khoom siv hauv tsev thiab cov khoom siv hluav taws xob: Feem ntau yog siv los ntsuas qhov ntsuas kub thiab tswj cov cua txias, cua sov, qhov cub thiab lwm yam khoom siv hauv tsev thiab khoom siv hluav taws xob.

3).Nkoj thiab aviation: feem ntau yog siv rau hauv kev tswj kub ntawm cov khoom siv high-end, xws li lub dav hlau, dav hlau, thiab lwm yam.

4).Kev tshawb nrhiav kev tshawb fawb: Nws kuj tau siv dav hauv kev tshawb fawb tshawb fawb los ntsuas qhov kub thiab txias, xws li kev sim tshuaj, kev sim tshuaj lom neeg, thiab lwm yam.

Feem ntau hais lus, lub caij nplooj ntoos hlav bimetallic muaj qhov zoo ntawm kev ntsuas siab, cov lus teb ceev ceev, lub neej ua haujlwm ntev, thiab cov qauv yooj yim.Nws yog dav siv nyob rau hauv ntau yam lag luam thiab yog ib qho kev lag luam thiab kev ntsuas kub ntsuas.